GW pipeline type non-clogging sewage pump

Date:2021-12-01 Click:360 Share to:

Product Advantages

1. It is directly connected to the motor and is coaxial. It is a mechatronic product with compact structure and stable performance.

2. The design of the anti-clogging hydraulic components of the large flow channel greatly improves the dirt passing capacity. It can effectively pass the 5 times the diameter of the pump diameter and the solid particles with the diameter of about 50% of the pump diameter.

3. Reasonable design, reasonable supporting motor, high efficiency, low noise, and significant energy saving effect.

4. The mechanical seal adopts hard wear-resistant tungsten carbide, which is durable and wear-resistant, and can make the pump safe and continuous operation for more than 8000 hours.

5. The pump is a vertical structure, the inlet and outlet centers are on the same horizontal line, and the inlet and outlet flange specifications are the same, so installation and disassembly are very convenient.

6. The area is small, no need to build a computer room, which can save a lot of infrastructure costs. A protective cover is added to the fan end of the motor, and the whole machine can be placed in outdoor work.

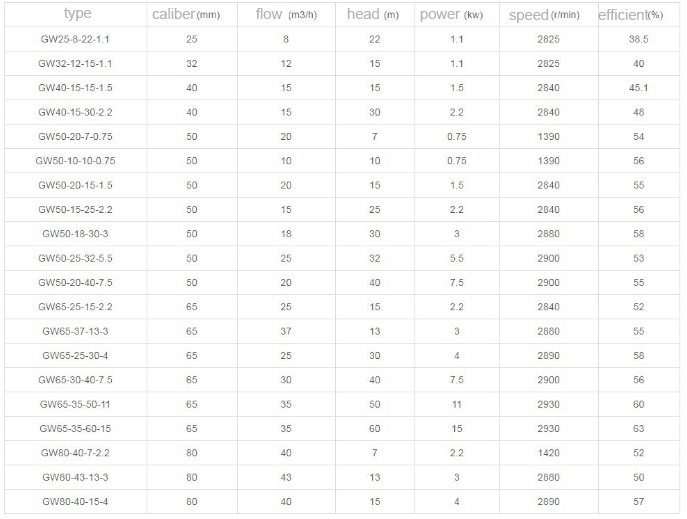

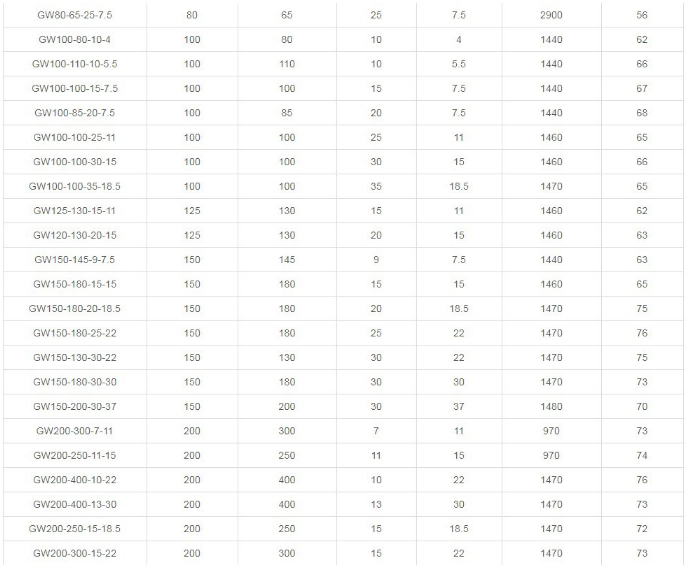

Performance Parameter

This data is for reference only, please refer to the actual order.

1. First check whether the external parts are loose during transportation.

2. Check whether the power supply voltage meets the requirements of the motor nameplate.

3. Turn on the power and make a trial run to see if the impeller is turned in the direction indicated on the pump. If the direction is reversed, adjust any two-phase line in the cable. The trial run should not take too long. Seals.

4. Install the pump and start it up and running. It is best to install the pump foot screws.

Maintenance

1. Before using the pump, check the insulation resistance of the motor winding to the casing. If it is less than 0.5 megohm, the stator must be dried and can be used after the insulation resistance rises.

2. If the gap between the impeller and the oil seal at the inlet of the pump body exceeds 2mm, the wear-resistant oil seal should be replaced.

3. When the pump seal leaks, the seals should be replaced in time. When replacing the seal, first install the seal flat, and then install the dynamic seal on the shaft.

4. When replacing the impeller, pull it out with a tensioner. Don't hit it with a hammer to destroy the axis.

Troubleshooting

1. No water. The pumped liquid is heavy and the particle size is too high; the liquid flow path is blocked; the impeller turns in the wrong direction; the rod is drawn into the impeller and is jammed; the outlet height of the pipe exceeds the rated lift height.

2. Insufficient flow and low lift. The voltage is low, the impeller is turned or the wear-resistant seal is worn; the liquid is heavy and the particle size is too high.

3. The insulation resistance is low, the surrounding environment is humid, and the mechanical seal is seriously leaking.

Factory shots

Factory shots

*FAQ

Q: Why choose Bochi?

A: 1. Excellent service before purchasing

Bochi know what the best cost-effective spare parts are. According to clients circumstances, we will recommend most suitable parts for them.

2. Guaranteed quality

Most products which Bochi are sold all over the worlds with high quality and also provide warranty to security benefits.

3. Rich experience and resources of various manufactures

Bochi has enormous resources of various manufacturers and distributors. Not only we are able to supply large quantity order, but also we can organize small quantity complex order as well.

For more information, please contact us!

ChatOnline

ChatOnline